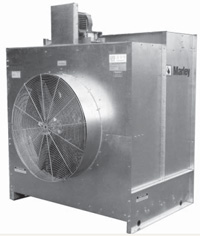

ACT Series Cooling Tower

- Home

- Cooling Towers

- ACT Series

Options

Special motors, such as two-speed, one-wind 460 volt, 60 cycle, 3 phase TEFC motors

Field assembly – with complete step-by-step instructions – for unique space restrictions or rigging conditions

Galvanized vertical discharge hood for use in restrictive enclosures or other site situations where horizontal discharge is not desirable

Component basin heater to prevent sump freezing during shutdown periods in winter operation (unnecessary when employing an indoor tank).

Pre-assembled submersible basin heater with built-in thermostat that maintains 40°F water.

Factory-installed control center in NEMA enclosure complete with thermostat controller for single or two-speed motors to maintain temperature.

Bottom outlet.

Non-corrosive stainless steel water basin.

ACT Series Cooling Tower

8 to 126 Tons

All Season Performance

The ACT Series performs as specified in the heat of summer—responding to energy-management techniques in the spring and fall—and operating virtually ice-free in the dead of winter.

Features

- Drift eliminators limit drift losses to no more than .010% of the design GPM flow rate.

- Thermoformed PVC film fill with integral louvers keep circulating water confined to fill, even at low air rates.

- Fill sheets – which can withstand temperatures up to 125°F – include integral louvers and drift eliminators designed to minimize resistance to airflow.

- Collection basin reduces operating weight, simplifies basin cleaning and assures proper outflow.

- Belt-drive propeller fans ensure design airflow at minimum horsepower.

- Screened suction connection.

- Threaded overflow connection.

- Threaded and plugged drain connection.

- Float-operated make-up valve.

- Fan guards andbelt guards.

*Marley and UNIBASIN are registered trademarks of SPX Cooling Technologies, Inc.

Want more details?

Please click on below button for a quick quote Or just call us now.